How to Inspect Your Furnace Flue Pipe for Each Heating Season

Maintenance of furnace flue pipes is critical to the safety and efficiency of a heating system. The flue pipe is responsible for venting combustion gases out of the home, so ensuring its integrity helps prevent hazards such as carbon monoxide leaks and ensures the furnace operates at its best. Regular inspections of the flue parts each heating season are essential to identify and address any issues early, maintaining a safe and functional heating system.

Table of Contents

What is a furnace flue pipe and what are its main components?

A furnace flue pipe is a pipe or duct that connects the furnace or boiler to the outside, serving as a pathway for exhaust gases produced during the combustion process to exit the building.

Components:

- Furnace vent pipe: The main elongated pipe that extends from the furnace to the exterior of the building, typically made of metal.

- Draft hood: A device located near the furnace that helps regulate the draft and ensures the proper venting of gases.

- Flue collar: The connection point where the flue pipe attaches to the furnace or boiler.

- Flue cap: A protective cover at the top of the vent pipe to prevent debris, animals, or rainwater from entering the pipe.

Purposes:

- Gas venting: The primary purpose of the furnace exhaust pipe is to safely vent harmful combustion byproducts, such as carbon monoxide, sulfur dioxide, and nitrogen oxides, out of the building.

- Preventing backdrafts: By creating a clear and direct path for exhaust gases to exit, the flue pipe helps prevent backdrafts that could lead to a buildup of dangerous gases inside the home.

- Maintaining indoor air quality: Properly functioning flue pipes ensure that indoor air quality remains high by expelling pollutants and gases that could be harmful to health.

- Efficiency: A well-designed and maintained flue pipe contributes to the efficient operation of the heating system by allowing gases to flow freely without obstruction, ensuring optimal combustion.

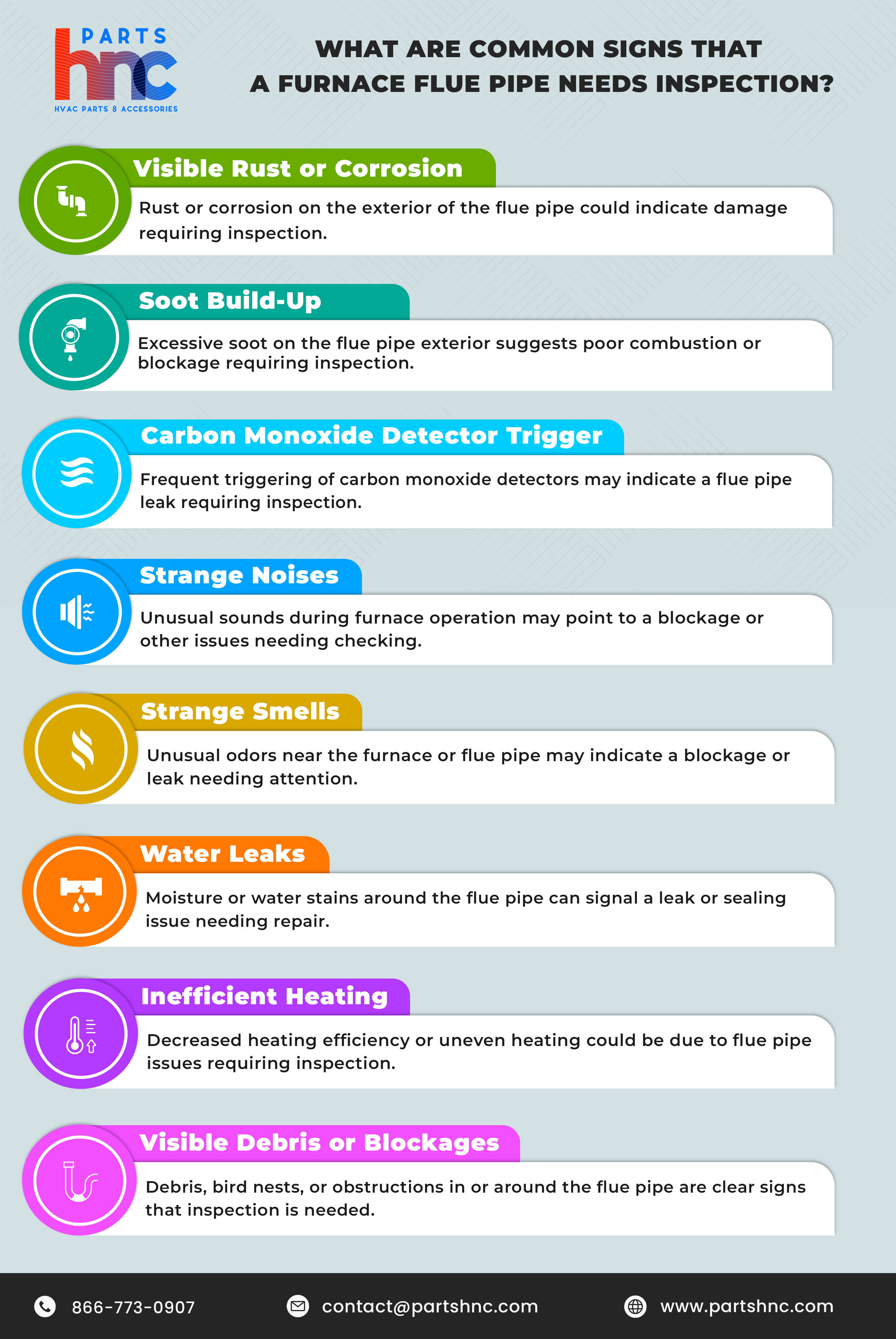

Common signs of a furnace flue pipe need inspection

Common signs that indicate a furnace flue pipe needs inspection include:

Checkout: The Ultimate Guide To Choosing The Right Furnace For Your Home: Everything You Need To Know

Furnace flue pipe requirements and tools for inspection

- Flashlight: Ensure you have a bright flashlight to inspect the inside of the flue pipe.

- Screwdriver: A screwdriver will be useful for removing any panels or covers from the furnace or flue pipe.

- Cleaning brush: Have a suitable brush to remove debris or soot from the flue pipe.

- Gloves and safety goggles: Wear protective gloves and safety goggles to safeguard against any debris or sharp edges during the inspection.

- Carbon monoxide detector: A functioning carbon monoxide detector is crucial to ensuring safety during the inspection.

How to inspect a furnace flue pipe?

To inspect a furnace exhaust pipe on roof, follow these steps:

- Turn off the furnace: Ensure the furnace is turned off to avoid any potential hazards during the inspection.

- Allow cooling time: If the furnace has been running, allow it sufficient time to cool down before starting the inspection.

- Visual examination: Use a flashlight to visually inspect the interior and outside furnace exhaust pipe for the following:

- Signs of rust, corrosion, or damage

- The presence of any debris, soot, or blockages

- Proper sealing at all connections and joints

- Carbon monoxide detector test: Use a carbon monoxide detector to ensure no leaks or potential hazards are emanating from the flue pipe.

- Cleaning: Remove any debris, soot, or obstructions from the flue pipe using a cleaning brush. Ensure proper airflow and ventilation.

- Sealing inspection: Check all connections and seals to ensure they are intact and effectively preventing gas leaks.

- Observe safety precautions: Throughout the inspection, adhere to the following

- Addressing issues: If any issues are identified, such as corrosion, blockages, or poor sealing, consult a technician for furnace flue pipe installation and necessary repairs.

Refer: How much does Furnace repair cost?

Addressing common furnace flue pipe issues

- Removing debris or blockages: If the inspection reveals the presence of debris or blockages within the flue pipe, these should be removed carefully to restore proper ventilation and prevent potential hazards.

- Repairing Damaged Sections: In the event of identified damage to specific sections of the flue pipe, it is imperative to repair these areas promptly. Professional assistance may be necessary to ensure proper and lasting repairs.

- Replacing Corroded Parts: Corrosion of flue pipe components, such as the vent pipe or flue cap, should be addressed by replacing the affected parts with new, corrosion-resistant materials to prevent structural compromise and gas leaks.

Safety measures during flue pipe inspection

|

Safety measures |

Description |

|

Turn off the furnace |

Ensure the furnace is powered off before starting the inspection to prevent potential hazards. |

|

Use protective gear |

Wear gloves and safety goggles to protect against debris, sharp edges, or contaminants during the inspection. |

|

Allow cooling time |

If the furnace has been running, allow it to cool down adequately to prevent burns or accidents. |

|

Carbon monoxide detector |

Have a functioning carbon monoxide detector nearby to monitor for leaks or hazardous gas emissions. |

|

Proper ventilation |

Ensure the inspection area has sufficient ventilation to prevent the buildup of harmful gases or fumes. |

|

Inform household members |

Notify other occupants about the inspection to maintain a safe environment and prevent interference. |

|

Professional assistance |

Follow furnace flue pipe code regulations governing furnace flue pipes are typically outlined in building codes, such as the International Mechanical Code (IMC) or the National Fuel Gas Code (NFPA 54). If unsure or dealing with complex issues, seek the expertise of a certified HVAC technician for safety and proper assessment. |

Regular inspection of your furnace flue parts each heating season is a fundamental aspect of responsible homeownership and essential to maintaining a safe and efficient heating system. Understanding components and signs of potential issues related to the flue pipe empowers homeowners to address any concerns and minimize safety hazards proactively. Furthermore, issues like debris removal, repairs, and part replacements discovered during inspection, as well as prioritizing safety measures during maintenance, ensure the continued integrity and functionality of the exhaust pipe from furnace flue pipe HVAC systems. By adhering to these practices, homeowners can uphold the safety, efficiency, and longevity of their heating systems.

FAQs

Is furnace exhaust dangerous?

Yes, furnace exhaust can be dangerous, especially if it contains carbon monoxide or other harmful gases. Carbon monoxide is a colorless, odorless gas that can be lethal if inhaled in high concentrations.

How hot does a furnace flue pipe get?

A furnace flue pipe can reach temperatures of 300 to 500 degrees Fahrenheit during normal operation.

How much does furnace flue pipe replacement cost?

The cost of replacing a furnace flue pipe typically ranges from $

300 - 1500$, depending on the material, length, and complexity of the installation.

What is a flue pipe?

A flue pipe is a venting pipe that safely expels combustion gases, such as carbon monoxide, from a furnace or other heating appliance to the outdoors.

How to clean furnace intake pipe

To clean a furnace intake pipe, use a vacuum cleaner or a brush to remove any dust, debris, or blockages, ensuring proper airflow for the heating system.

Loyalty Program

Loyalty Program