Troubleshooting Common Issues with Lennox Furnace Pressure Switches

Troubleshooting issues with a pressure switch on Lennox furnace is crucial for maintaining the efficient and safe operation of your heating system. The pressure switch plays a vital role in ensuring proper airflow and ventilation before allowing the furnace to ignite, making it a critical component in the overall functionality of the HVAC system. In this blog, we will explore common problems that may arise with Lennox furnace pressure switches and provide valuable insights into diagnosing and resolving these issues effectively.

Table of Contents

- What is the role of the Lennox furnace pressure switch?

- Lennox Furnace High and Low-Pressure Switches

- Symptoms of a Faulty Lennox Furnace Pressure Switch

- How to Test a Pressure Switch on a Furnace?

- Troubleshooting Furnace Pressure Switch Hose Issues

- What Is the Cost of a Lennox Furnace Pressure Switch?

- FAQs

What is the role of the Lennox furnace pressure switch?

A pressure switch is an essential safety and control device used in various HVAC systems, including furnaces, to monitor the air pressure or airflow within the system and ensure proper operation. The pressure switch acts as a safety measure by detecting the presence or absence of adequate pressure, which then triggers or prevents certain operations within the system based on predefined parameters.

When the furnace cycle begins, the inducer motor creates a draft to ensure proper ventilation. The pressure switch monitors the airflow created by the inducer motor and confirms that it is operating within the specified range. If the pressure switch detects the appropriate airflow, it signals to the control board that it is safe to proceed with igniting the furnace or allowing the heating cycle to commence.

Lennox Furnace High and Low-Pressure Switches

- High-Pressure Switch: In the context of a Lennox furnace, a high-pressure switch is not commonly used. Typically, high-pressure switches are found in air conditioning systems and refrigeration units to prevent the system from operating when the refrigerant pressure exceeds safe levels.

- Low-Pressure Switch: A low-pressure switch is also not a standard component in a Lennox furnace. In other HVAC systems, a low-pressure switch is used to prevent the system from operating when the pressure falls below a safe threshold, indicating potential issues such as refrigerant loss in air conditioning systems.

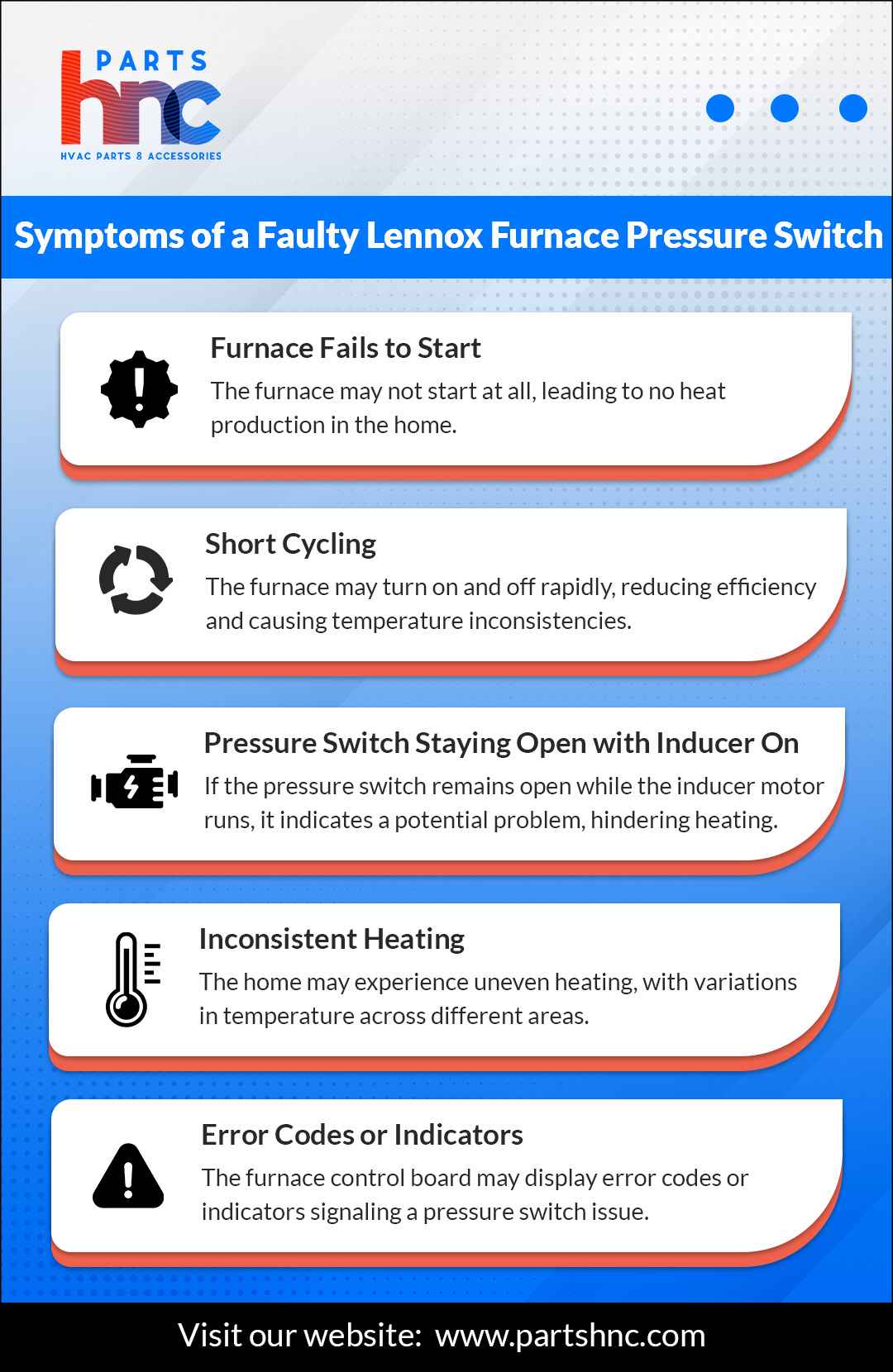

Symptoms of a Faulty Lennox Furnace Pressure Switch

How to Test a Pressure Switch on a Furnace?

Testing a pressure switch on a Lennox furnace is essential to ensure proper operation and safety.

- Turn off power: Before testing the pressure switch, turn off power to the furnace to prevent electrical hazards.

- Locate pressure switch: Locate the pressure switch in the furnace. It is typically near the inducer motor and connected by tubing to the combustion chamber.

- Remove wires: Disconnect the wires attached to the pressure switch terminals. Take note of their original placements for reconnection.

- Set multimeter: Set your multimeter to measure resistance (ohms) on an appropriate scale.

- Test continuity: Place the multimeter probes on the pressure switch's terminals to check for continuity. A reading of zero or very low resistance (closed circuit) indicates continuity.

- Apply pressure: If your pressure switch has multiple pressure settings, apply pressure to the switch to simulate the conditions that would cause it to close.

- Check operation: Observe the multimeter readings to confirm that the pressure switch closes and opens as expected based on pressure changes.

- Reconnect wires: Once testing is complete and the pressure switch functions correctly, reconnect the wires to their respective terminals.

- Turn On power: Restore power to the furnace and test its operation to verify that the pressure switch is functioning properly.

- Testing furnace pressure switch: Checking the continuity and functionality of the Lennox pressure switch is crucial for ensuring the safe and efficient operation of the furnace. The pressure switch plays a vital role in confirming proper airflow and ventilation before allowing the furnace to ignite.

Troubleshooting Furnace Pressure Switch Hose Issues

|

Problem |

Symptoms |

Solution |

|

Clogging or blockage |

Improper pressure readings lead to pressure switch malfunction. |

Inspect the hose for obstructions like dirt or debris. Clear blockages using compressed air or a small brush. |

|

Damage or wear |

Leaks or inaccurate pressure readings due to cracks, tears, or deterioration of the hose. |

Check the entire hose for damage. Replace the hose if any issues are found to ensure a proper seal and accuracy. |

|

Incorrect installation |

Air leaks or misalignments cause incorrect pressure readings. |

Ensure secure connections at both ends of the hose. Verify there are no kinks or pinches that could disrupt airflow. |

|

Condensation build-up |

Accumulation of condensation in high-efficiency furnaces, affecting pressure readings. |

Check for condensation in the hose. Ensure the condensate trap and drainage system work properly; insulate if needed. |

Lennox furnace pressure switch open with inducer on: This issue occurs when the pressure switch remains open despite the inducer motor running. It suggests that the switch is not detecting the expected airflow, potentially due to a clogged vent, a malfunctioning inducer motor, or a faulty pressure switch itself. This situation indicates that the system's safety mechanisms are functioning properly to prevent the furnace from igniting under unsafe conditions.

Unlock the secrets to a cleaner furnace heat exchanger with our ultimate guide

What Is the Cost of a Lennox Furnace Pressure Switch?

- Furnace pressure switch cost: The typical cost to replace a furnace pressure switch can vary based on factors such as the type of furnace, the specific pressure switch model, and labor fees if professional installation is required. On average, the price of a replacement furnace pressure switch can range from $50 to $200, with high-efficiency or specialized switches potentially costing more.

- Cost to replace furnace pressure switch

When factoring in professional installation, the total cost may increase to around $150 to $400 or more, depending on the service provider's fees and the complexity of the installation process.

Get your furnace running smoothly again with a furnace control board replacement

By understanding the role of the pressure switch and checking for issues with the pressure switch hose, homeowners can address potential problems proactively. Common issues such as clogging, damage, incorrect installation, and condensation buildup in the pressure switch hose can impact the functionality of the pressure switch. Identifying and resolving these issues promptly, can prevent system malfunctions, ensure proper airflow and ventilation, and optimize the performance of the Lennox furnace. PartsHnC offers a wide selection of HVAC furnace parts, including gas valves. Thermocouples Ignitors Flame Sensors All parts are competitively priced, and we ensure same-day shipping for your convenience.

FAQs

How do I reset the Lennox furnace pressure switch?

To reset the Lennox furnace pressure switch, turn off the power to the furnace, wait for a few minutes, then restart the system. If the pressure switch continues to trip, it may indicate an underlying issue that requires further troubleshooting.

Why is the Lennox pressure switch tripping?

The Lennox pressure switch may trip due to issues such as clogging in the pressure switch hose, a faulty pressure switch, inadequate airflow, or problems with the inducer motor. Troubleshooting these components can help resolve the tripping issue.

How to Check a Pressure Switch on a Furnace?

Use a multimeter to test the switch and inspect the tubing and connections for blockages or damage. Verify the inducer motor is running properly, clean the pressure switch and surrounding components

How do Lennox furnace error codes help diagnose pressure switch issues?

Lennox furnace error codes provide specific indicators that can help identify pressure switch malfunctions, such as codes indicating blocked vents, improper pressure readings, or failures to close. By referencing these codes, technicians can quickly pinpoint and resolve issues affecting the furnace's operation.

Loyalty Program

Loyalty Program