How to Replace the York Water Temperature Sensor in HVAC Systems

In HVAC systems, the water temperature sensor holds significant importance as a critical component responsible for monitoring and regulating the temperature of the water. This sensor plays a key role in ensuring precise temperature control within the system, ultimately contributing to efficient operation, energy savings, and optimal performance. Understanding the vital function of the water temperature sensor in York HVAC systems is essential for maintaining reliable cooling processes and maximizing system efficiency. Additionally, recognizing common issues that signal a failing water temperature sensor is crucial for timely diagnosis and replacement, ultimately safeguarding the system's functionality and longevity.

Table of Contents

- What Does a Water Temperature Sensor Do?

- Importance of Accurate Temperature Monitoring

- Signs of a Faulty Water Temperature Sensor

- Types of HVAC Machinery Using Water Temperature Sensors

- Types of Water Temperature Sensors Used in HVAC Systems

- Step-by-Step Guide to Replacing the York Water Temperature Sensor

- Troubleshooting Common Problems of the York Water Temperature Sensor

- Tips for Maintaining the Water Temperature Sensor

- FAQs

What Does a Water Temperature Sensor Do?

The water temperature sensor in an HVAC system, such as those used in York equipment, plays a critical role in monitoring and regulating the system's water temperature. It is responsible for providing real-time data on the temperature of the water circulating within the HVAC system, allowing the system to adjust its operations to maintain the desired temperature levels. This information is essential for enabling precise control over the heating or cooling processes, ensuring that the HVAC system can efficiently meet the specific demands for comfort or industrial processes. Additionally, the water temperature sensor provides crucial input for the system's overall efficiency, as it directly influences the energy consumption and performance of the HVAC equipment.

Importance of Accurate Temperature Monitoring

Accurate temperature monitoring facilitated by the water temperature sensor is integral to the efficient and reliable operation of the system. Proper temperature regulation is essential for maintaining the optimal level and ensuring energy efficiency. A malfunctioning sensor can lead to inaccurate temperature readings, potentially resulting in the system operating outside of the desired temperature range. This can impede the system's ability to provide effective cooling, leading to increased energy consumption, reduced operational efficiency, and potential strain on the chiller's components.

Signs of a Faulty Water Temperature Sensor

|

Sign |

Description |

|

Erratic temperature readings |

Inconsistent or inaccurate temperature readings on the control panel, not matching the actual water temperature. |

|

Chiller shutdowns |

A malfunctioning sensor may cause chiller shutdowns or interruptions to prevent damage or operational issues. |

|

System errors or alarms |

Occurrence of system errors or alarms related to temperature regulation, signaling potential sensor issues. |

|

Inefficient operation |

Sensor failure can lead to inefficient cooling, increased energy consumption, and reduced system performance. |

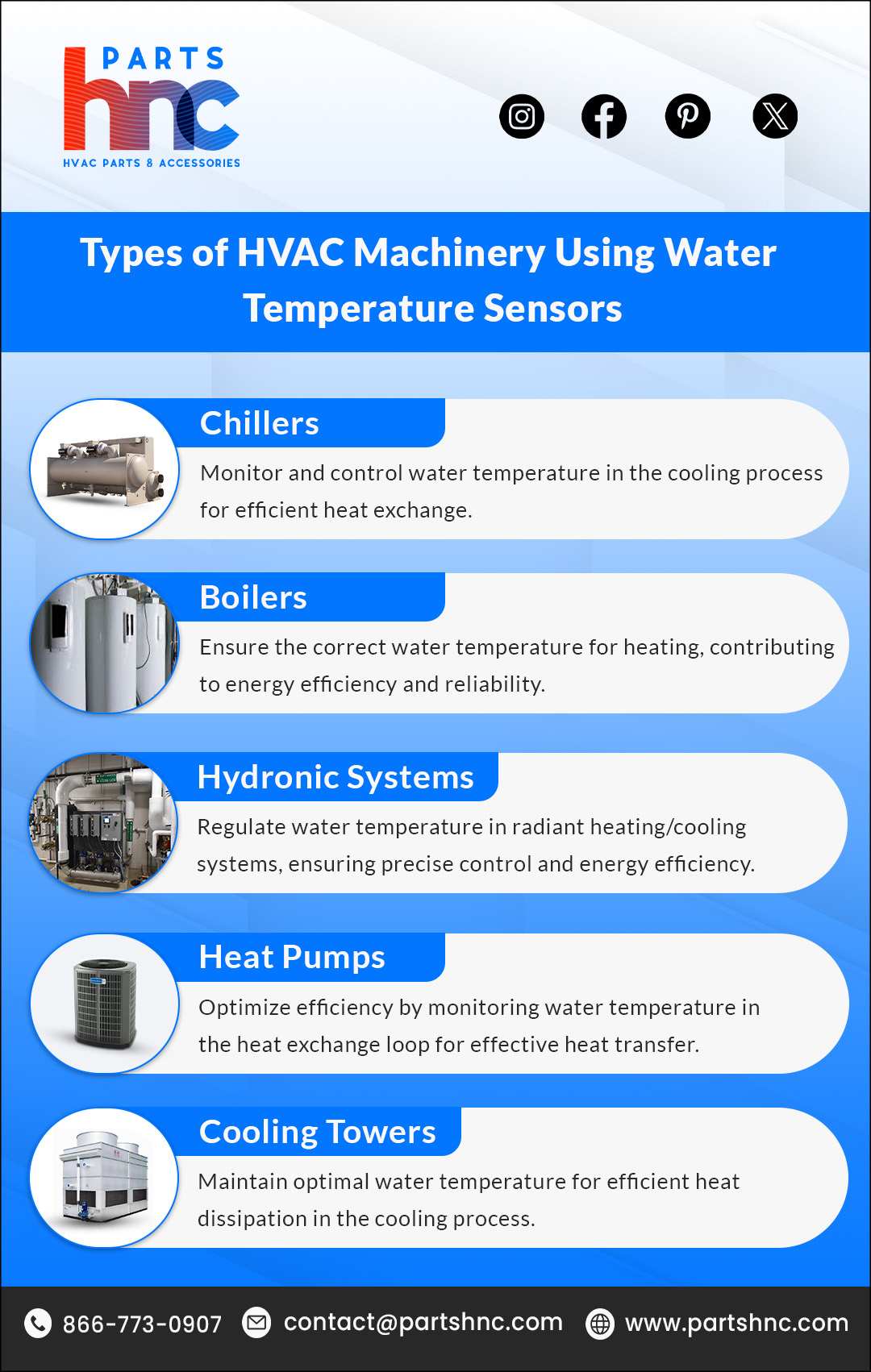

Types of HVAC Machinery Using Water Temperature Sensors

Types of Water Temperature Sensors Used in HVAC Systems

|

Sensor Type |

Overview |

HVAC Applications |

|

Generate a voltage based on the temperature difference between two dissimilar metals. |

Used for hydronic systems temperature sensing in water boilers, water chillers, and HVAC cooling towers. |

|

|

Thermistors |

Change resistance with temperature variations for precise measurements. |

Ideal for accurate and reliable temperature monitoring, especially in applications requiring precise control. |

|

Resistance Temperature Detectors (RTDs) |

Utilize metal resistance (typically platinum) for high accuracy and stability. |

Employed in high-precision temperature control systems, such as commercial refrigeration and climate control. |

|

Integrated Circuit (IC) Sensors |

Offer digital temperature measurement and ease of integration. |

Used in underwater sensors in modern HVAC systems for precise temperature readings and advanced control capabilities. |

|

Infrared Temperature Sensors |

Measure temperature by detecting infrared radiation, allowing non-contact measurement. |

Used for non-contact temperature measurement of HVAC components, ductwork, and inaccessible areas. |

Here is our detailed guide on parts of HVAC system for your reference: What Are The Most Important Parts Of Your HVAC Systems?

Step-by-Step Guide to Replacing the York Water Temperature Sensor

Locate the Water Temperature Sensor

- Refer to the system manual to identify the exact location of the water temperature sensor within your York HVAC system. The sensor is typically located at a point where it can accurately measure the temperature of the water.

Disconnect the Power and Drain the system

- Before starting any work, ensure that all power to the HVAC system is disconnected to prevent electrical hazards.

- If applicable, drain the water from the chiller system to avert leaks and ensure a safe working environment when removing the sensor.

Remove the Existing sensor

- Carefully use a suitable wrench or screwdriver to disconnect the existing water temperature sensor from the system. Take note of the wiring connections or take a clear photo for reference before removing the sensor.

Install the New Sensor

- Align the new water temperature sensor in the same position as the old one, ensuring that it is securely fitted into place.

- Reconnect the wiring to the new sensor, making sure that all connections are secure and match the original setup.

Refill the System and Reconnect Power

- Refill the chiller system with water, taking care to check for any leaks around the new sensor and addressing any issues if they arise.

- Once the sensor is installed and the system is filled, reconnect the power to the HVAC system, ensuring all safety protocols are followed.

Test the New Sensor

- Power on the HVAC system and carefully monitor the water temperature readings to ensure that the new sensor is functioning as expected.

- Use a multimeter to verify the accuracy of the temperature readings from the new sensor, confirming that it is providing reliable data for temperature control within the chiller system.

Troubleshooting Common Problems of the York Water Temperature Sensor

No Temperature Reading

- First, ensure that the water temperature sensor is correctly connected to the HVAC system according to the manufacturer's guidelines. Check for any loose or disconnected wiring.

- Confirm that the system is powered on and operational. If there is still no temperature reading, the sensor may be faulty and require replacement.

Inaccurate Temperature Readings

- Verify that the water temperature sensor is appropriately placed in the chiller system, as per the manufacturer's recommendations. An incorrectly positioned sensor can lead to inaccurate temperature readings.

- Check all wiring connections to ensure they are secure and undamaged. Loose or damaged connections can interfere with the sensor's functionality, resulting in inaccurate readings.

System Errors After Installation

- If system errors occur after installing the new water temperature sensor, double-check the wiring to ensure that it matches the original setup and that all connections are secure. Confirm that the sensor is compatible with the HVAC system.

- Consider resetting the system according to the manufacturer's instructions. A system reset may help resolve any errors that arose during or after the installation process.

Tips for Maintaining the Water Temperature Sensor

|

Tip |

Description |

|

Regular inspections |

Periodically inspect the water temperature sensor and HVAC components for wear, corrosion, or damage. Address issues promptly to prevent system malfunctions. |

|

System maintenance |

Schedule regular servicing for the entire HVAC system, including the chiller unit, to prevent sensor failures and ensure optimal performance. |

|

Proper sensor calibration |

Ensure the water temperature sensor is correctly calibrated to maintain accurate temperature readings and reliable system operation. |

Ever wonder what the HVAC safety standards? Here is our guide on Mitigating Hazards: Best Practices in HVAC Safety Standards

Replacing the water temperature sensor in a York HVAC system is a critical maintenance task that can significantly impact the system's performance and energy efficiency. By following the proper procedures for identifying, removing, and installing the sensor, as well as conducting thorough testing and calibration, HVAC technicians can ensure that the chiller system operates effectively and maintains the desired temperature levels. Regular maintenance and prompt replacement of faulty sensors are essential practices to sustain the reliability and functionality of HVAC systems, contributing to enhanced performance and energy savings. PartsHnC provides a wide range of York HVAC parts, York chiller parts, and boiler parts, including thermocouples, thermistors, and sensors. Find the replacement parts you need to meet your requirements.

FAQs

How often should the water temperature sensor be inspected for signs of wear?

Regular inspections should be conducted as part of routine HVAC system maintenance, typically at least once per year.

Why is it required to calibrate the water heater temperature sensor?

After installing the new water heater temperature sensor, it is crucial to calibrate the new sensor properly to maintain precise temperature readings.

How does an electric water temperature gauge work?

An electric water temperature gauge typically contains a temperature sensor that measures the temperature of the water.

Loyalty Program

Loyalty Program