Understanding the Role of the Heat Pump Compressor: A Comprehensive Guide

The heat pump compressor is an essential component of heat pump systems, acting as the primary pump of the refrigeration cycle and allowing for effective heating and cooling in indoor environments. Knowledge about the compressor's functions and significance is essential to understanding how heat pumps work and how effectively they regulate indoor temperatures. In this guide, we will look at heat pump compressors, how they work, how important they are in the heat pump system, and how they affect heat pumps' overall performance and energy efficiency.

Table of Contents

- What is a heat pump system?

- Types of heat pumps

- Understanding air compressors in heat pumps

- Components of a heat pump compressor

- Efficiency and performance considerations for heat pump compressors

- Common issues and troubleshooting for heat pump compressors

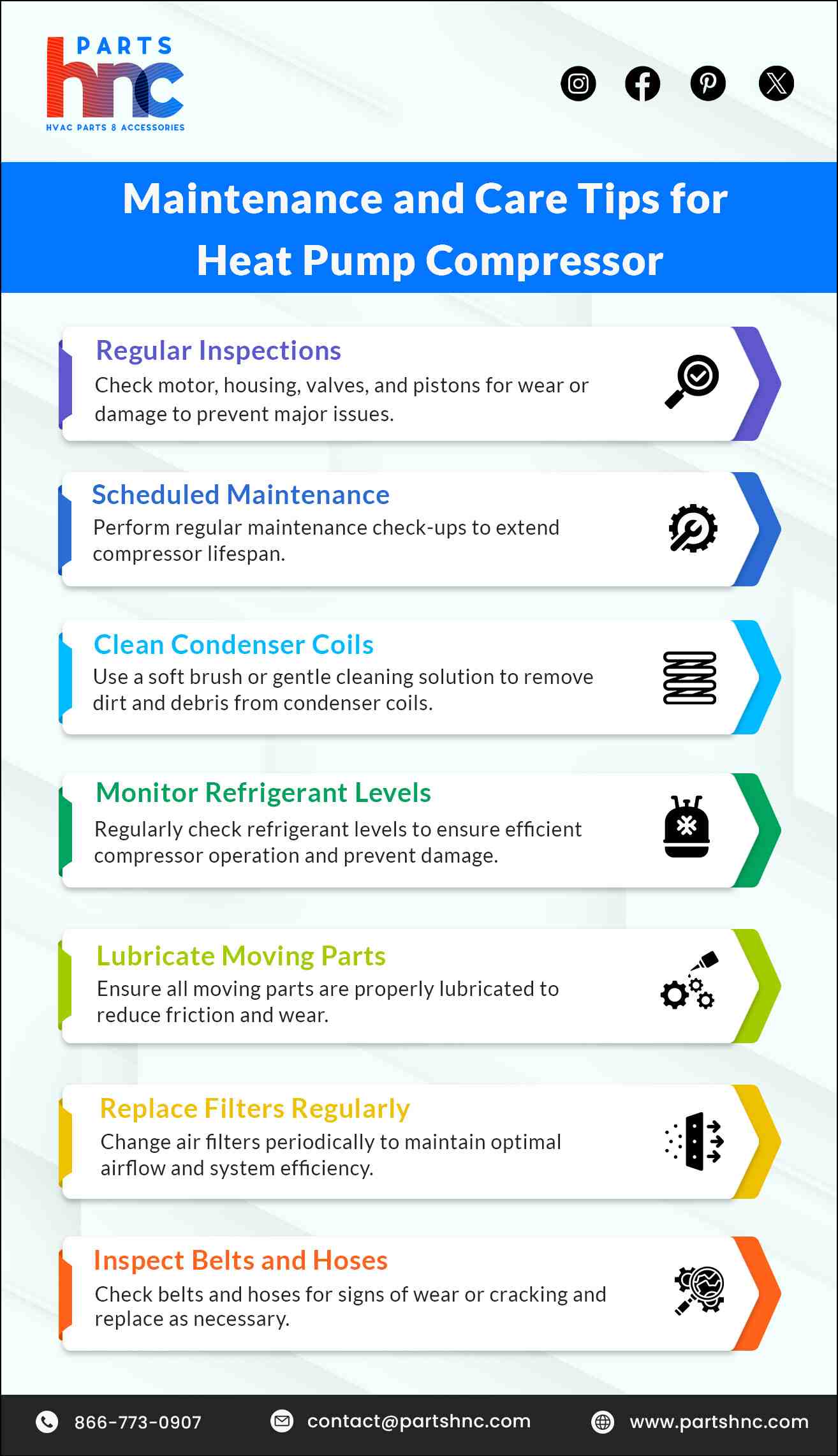

- Maintenance and care tips for heat pump compressors

- FAQs

What is a heat pump system?

A heat pump system is a versatile and energy-efficient heating and cooling technology that transfers heat between indoor and outdoor environments to regulate the temperature inside a building. Unlike traditional heating systems that generate heat, heat pumps move heat from one place to another, making them a sustainable solution for both heating and cooling needs.

Types of heat pumps

- Air-source heat pumps: These are the most common type of heat pumps, extracting heat from the outdoor air. They can operate in various climates but may be less efficient in extreme cold conditions.

- Ground-source heat pumps: These systems extract heat from the ground or a water source, offering high efficiency and consistent performance. They can be more costly to install, but they provide long-term energy savings.

- Water-source heat pumps: Water-source heat pumps use water from a nearby pond, lake, or well as a heat source or sink. They are efficient and reliable, but they require access to a water source.

Refer: How Much Will A Heat Pump System Cost?

Understanding air compressors in heat pumps

Basic operation

Air compressors play a crucial role in the operation of heat pumps by pressurizing refrigerant gases to facilitate the heat transfer process. When the refrigerant enters the compressor, it gets compressed, which increases its temperature and pressure. This high-pressure, high-temperature gas is then circulated through the system to release or absorb heat, depending on the heating or cooling mode.

Types of compressors used

- Scroll compressors: Scroll compressors are commonly used in heat pumps for their efficiency and quiet operation. They work by using orbiting and fixed scrolls to compress the refrigerant gas smoothly.

- Rotary compressors: Rotary compressors operate by rotating an off-center shaft to compress the refrigerant gas. They are compact, reliable, and suitable for smaller heat pump systems.

- Reciprocating compressor hvac: Reciprocating compressors use a piston-cylinder mechanism to compress the refrigerant gas. They are versatile, cost-effective, and commonly found in various heat pump compressors.

Components of a heat pump compressor

- Air compressor motor: The air compressor motor is the power source that drives the compressor in an air compressor system. It is responsible for converting electrical energy into mechanical energy, which is used to compress the refrigerant gas. air compressor automatic shut off is designed to stop running once it reaches a preset pressure level.

- Compressor housing: The compressor housing serves as the enclosure that houses and protects the internal components of the compressor, including the motor, valves, pistons, and other critical parts. The housing is designed to provide structural support, maintain proper alignment of components, and prevent external contaminants from entering the compressor.

- Valves and pistons: Valves and pistons are essential components within the compressor that play a key role in compressing and circulating the refrigerant gas. The valves control the flow of refrigerant in and out of the compression chamber, ensuring efficient compression and release of the gas.

Efficiency and performance considerations for heat pump compressors

- Energy efficiency ratings (SEER and HSPF): The efficiency of an air compressor and motor significantly impacts the overall SEER (Seasonal Energy Efficiency Ratio) and HSPF (Heating Seasonal Performance Factor) ratings of a heat pump system. Higher compressor efficiency results in lower energy consumption, which can improve the SEER and HSPF ratings.

- Variable speed compressors: Variable speed or modulating compressors offer several advantages for improving efficiency in heat pumps. These compressors can adjust their speed and capacity based on the heating or cooling demand, allowing for precise temperature control and optimized energy usage.

- Load matching and comfort control: Compressors play a critical role in load matching and comfort control within a heat pump system. The compressor adjusts its capacity to match the heating or cooling demands of the space, ensuring that the system operates efficiently and effectively.

Common issues and troubleshooting for heat pump compressors

|

Issue |

Description |

Troubleshooting steps |

|

Noises |

Unusual noises such as grinding, banging, or squealing come from the compressor and motor. |

Inspect for internal issues, such as loose or damaged components. |

|

Reduced efficiency |

System struggles to cool or heat effectively, indicating potential compressor problems. |

Check refrigerant levels, clean condenser coils, and inspect for any blockages or airflow issues. |

|

Failure to start |

Compressor fails to start or experiences frequent starting issues. |

Verify power supply, check for tripped breakers, and inspect the start capacitor and contactor. |

|

Electrical issues |

Compressor and motor not receiving power, or experiencing electrical issues like tripped breakers. |

Ensure power supply is intact, inspect wiring, and check for any tripped breakers or faulty electrical components. |

|

Low refrigerant levels |

Low refrigerant levels impacting the compressor's ability to function properly. |

Check for refrigerant leaks, and refill to appropriate levels as per manufacturer guidelines. |

|

Mechanical problems |

Visible signs of damage or wear on compressor components affecting performance. |

Inspect for damage or wear on components such as valves, pistons, and bearings, and replace if necessary. |

Checkout: Troubleshooting Heat Pumps: 6 Common Problems And Solutions

Maintenance and care tips for heat pump compressors

The heat pump compressor plays a crucial role in the efficiency and functionality of the heat pump system. It is essential to understand how the compressor functions to ensure optimal performance and longevity of the system. Additionally, proper maintenance of the compressor, including monitoring the air compressor pressure switch, regular check-ups of air compressor parts, using the best air compressor for the job, and ensuring a clean air compressor filter, can greatly impact the overall performance and lifespan of the heat pump system. By staying informed and proactive in caring for heat pump parts, you can enhance the efficiency and reliability of your heat pump for years to come.

FAQs

What factors determine the AC compressor size?

The size of an AC compressor is determined by the cooling capacity required for the space it will be used in.

What is the purpose of air compressor?

The main purpose of an air warm compressor is to convert power into potential energy stored in pressurized air.

What is air compressor?

An air compressor is a device that compresses air to generate power for various pneumatic tools and equipment. A compressor heater is used to prevent the refrigerant in the compressor from freezing in low-temperature conditions.

What does the compressor do in a refrigeration system?

The heater compressor in a refrigeration system is responsible for compressing and circulating refrigerant to transfer heat from inside to outside, cooling the space.

Loyalty Program

Loyalty Program